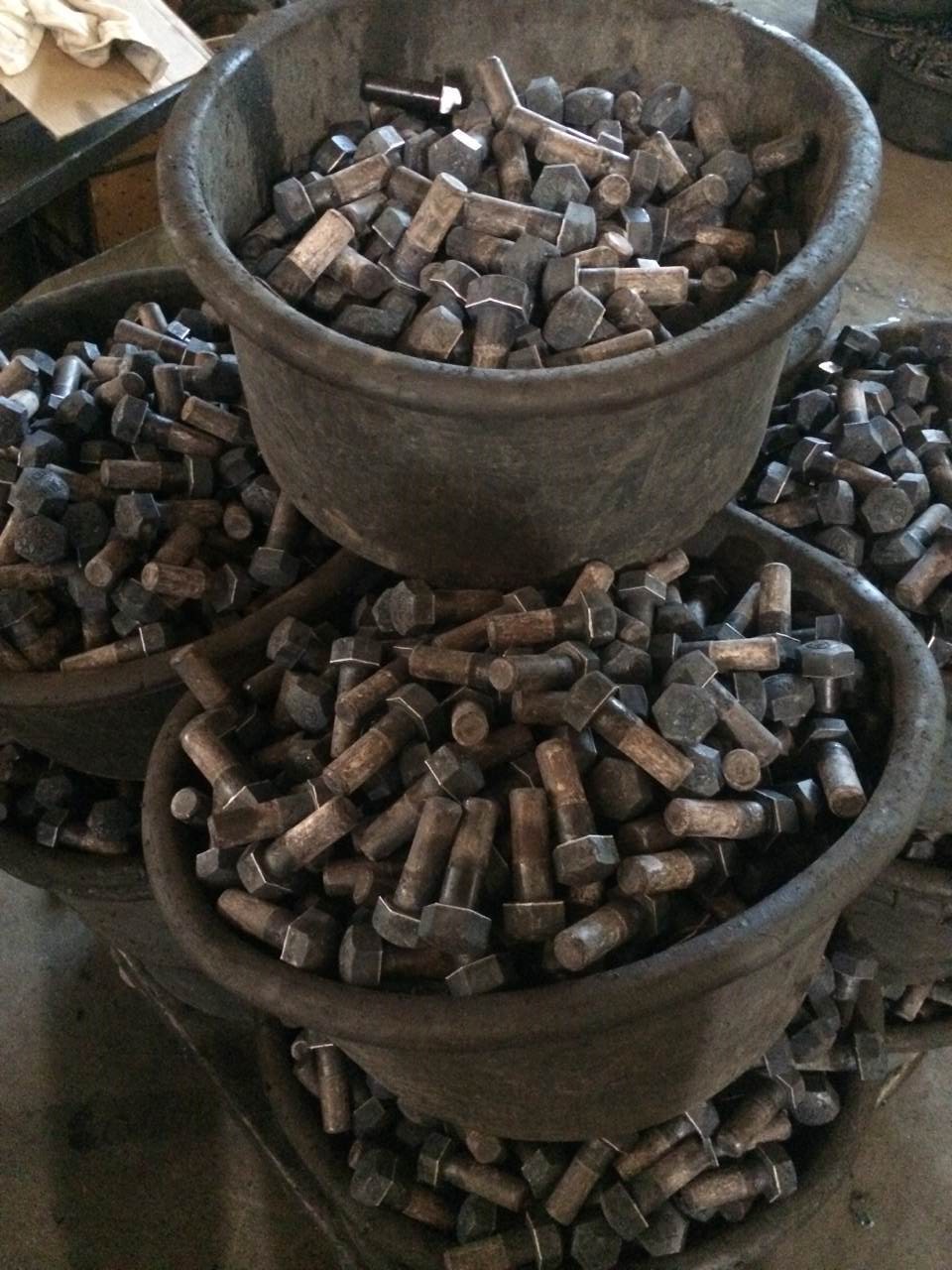

Ts'ebetso ea Morafo oa Bolt & Nut

Thepa e sebelisang 35 forging, le modulation heat treatment processing technology ho etsa bophahamo ba screw le nut le clearance haufi-ufi, eseng e hlephileng, e sa sebetseng, e thata haholoanyane le ho hanyetsa khatello, ha ho bonolo ho senya deformation, bophelo bo bolelele ba tšebeletso.The screw na le mefuta e 'meli ea UNF le UNC le tensile matla le compressive matla a ka fihla ho 8.8-12.9.

| Lintlha tse qaqileng tsa sehlahisoa | |

| Tlhaloso: | TŠEBELETSO EA BOLT & NUT MINING |

| Sebaka sa tsoalo: | China |

| Lebitso la lebitso: | PT'ZM |

| Nomoro ea mohlala | D11 |

| Theko: | Buisana |

| Lintlha tsa ho paka: | Mabokose le li-palltes |

| Nako ea thomello: | Matsatsi a 7-30 |

| Nako ea tefo: | L/CT/T |

| Theko ea nako: | FOB/ CIF/ CFR |

| Bonyane ba odara: | 1 PC |

| Matla a Phepelo: | 100000 PCS / khoeli |

| Boitsebiso: | 35CrMo |

| Mokhoa: | Ho qapa |

| Qetella: | Zinc(Yellow, White, Blue, Black), Hot Dip Galvanized(HDG), Black, Geomet, |

| Ho thatafala: | 8.8-12,9 |

| Boleng: | ts'ebetso ea merafo |

| Nako ea tiisetso: | 1 SELEMO |

| Tšebeletso ea ka mor'a thekiso: | Ts'ehetso ea tekheniki ea video, Ts'ehetso ea Marang-rang |

| Mmala: | Bosehla kapa bo Batšo kapa Moreki oa hlokahala |

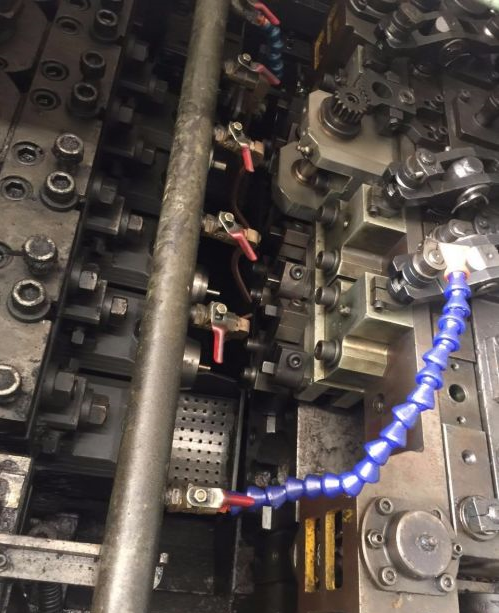

| Kopo: | Bulldozer & Crawler excavator |

1.Sekoahelo se etsoa ka terata ea 35Crmo e sa le pele hore e be sebopeho sa spiral.Hobane terata e tla holofala ebe e ba motenya ka mor'a ho etsoa, re hloka ho khetha molamu o mosesaane ho feta shaft ea screw ha o etsa screw. .

2.Thepa e fetisetsoa sebakeng se loketseng sa bolelele le ho otloloha ka thepa ea mochine, ebe e feptjoa mochine oa sehlooho o batang.

3. Ntlha ea pele, mokhatlo oa pele oa punch o etsa hore terata e itokisetse ho theha, ebe mokhatlo oa bobeli oa punch o boela o theha mohala le ho etsa sehlahisoa sa sona se felileng.Ha ho sebetsoa ka lihlooho tse batang, palo ea li-die-fixed dies (die) le stamping (flatten) dies (punch) ha e tšoane. Li-screws tse ling tse rarahaneng li ka hloka punch e fetang e le 'ngoe ka ho theha, e hlokang lisebelisoa tsa li-multi-station li ka etsa ho etsa screw.

4.Ka mor'a ho sisinyeha ha punch, hlooho ea screw e phethiloe, empa karolo ea screw shaft ha e na khoele.Mokhoa oa ho etsa mokhoa oa leino la khoele ea sekoti ke ho phunya terata.Rub khoele ke tšebeliso ea meno a mabeli a batlang a bilika a sekoti a ngotsoe ka khoele e hatellang die (rub plate) extrusion ka har'a setsi sa multi-station kapa punching machine processing cylindrical blank.

5.Ka mor'a ho qala le ho sila meno, sekoti kaofela se hlahisitsoe.Ehlile, molemong oa ho etsa hore ponahalo ea screw e be e khanyang le ts'ebetso e betere, ts'ebetso ea kalafo ea bokaholimo e tla etsoa ka kakaretso. joalo ka "stainless steel screw cleaning passivation", carbon steel screw surface plating, joalo-joalo E entsoe ka mebala e fapaneng ea li-screw fasteners.

6.Ha ho etsoa li-screw fasteners, ho lokela ho hlokomeloa hore sekoti se seng le se seng se hloka ho sebelisa mefuta e sa tšoaneng, kahoo li-screws tse sa tloaelehang li tla hloka ho bula hlobo e 'ngoe bakeng sa tlhahiso.

U mohoebi kapa u moetsi?

Re khoebo ea ho kopanya indasteri le khoebo, fektheri ea rona e fumanehang Quanzhou.Re khoebo ea sejoale-joale e sebetsanang le ho kopanya mochini oa kaho le likarolo tsa thepa le thekiso ea marang-rang.

Nka Netefatsa Joang Hore Karolo eo e Tla Tšoanela Sesepa sa Ka?

Re fe Nomoro e Nepahetseng ea Mohlala / Nomoro ea Mochini / Nomoro efe kapa efe likarolong ka botsona kapa u lekanye likarolo li re fa tekanyo kapa ho taka.

Ho thoe'ng ka Melao ea Tefo?

Hangata re Amohela T/T Kapa L/C.Lipehelo tse ling le tsona li ka buisanoa.

Ho thoe'ng ka Taolo ea Boleng?

Re na le Sistimi e phethahetseng ea QC bakeng sa Lihlahisoa tse Phethahetseng.Sehlopha se Tla Lemoha Boleng ba Sehlahisoa le Sekhechana sa Litlhaloso ka Hloko, Se Lekola Ts'ebetso E 'ngoe le E 'ngoe ea Tlhahiso Ho fihlela Ho Paka ho Felletse, Ho netefatsa Tšireletseho ea Sehlahisoa ka Setshelo.